【Wrinkle processing】

We reviewed the cotton paper making process from scratch and were able to produce a considerably strong paper. At the same time, a problem arose. It is no longer possible to wrinkle the paper with human fingers.

【making wooden frames】

We received a request to "try it on a chair seat." The seat of a chair is subjected to considerable weight when sitting on it. That is why we repeatedly experimented with materials to increase the strength of cotton leather. At the same time, we continued to collect modest data to solve the problems of the peculiar smell and difficulty in drying that

【natural plastic rubber】

It would dry more quickly if lead or other substances were added, but since we are engaged in slow manufacturing with no environmental impact, we continued to feed air for three months. The liquid has turned into a strange rubbery substance.

【Prototype of round handle】

It is also necessary to strain the cotton paper thin. At the same time, it must be tough or it will lose its strength in the process. We are now trying a method where the paper is hand-stretched until it is wrinkled, and then it is wrapped around the core of the rattan.

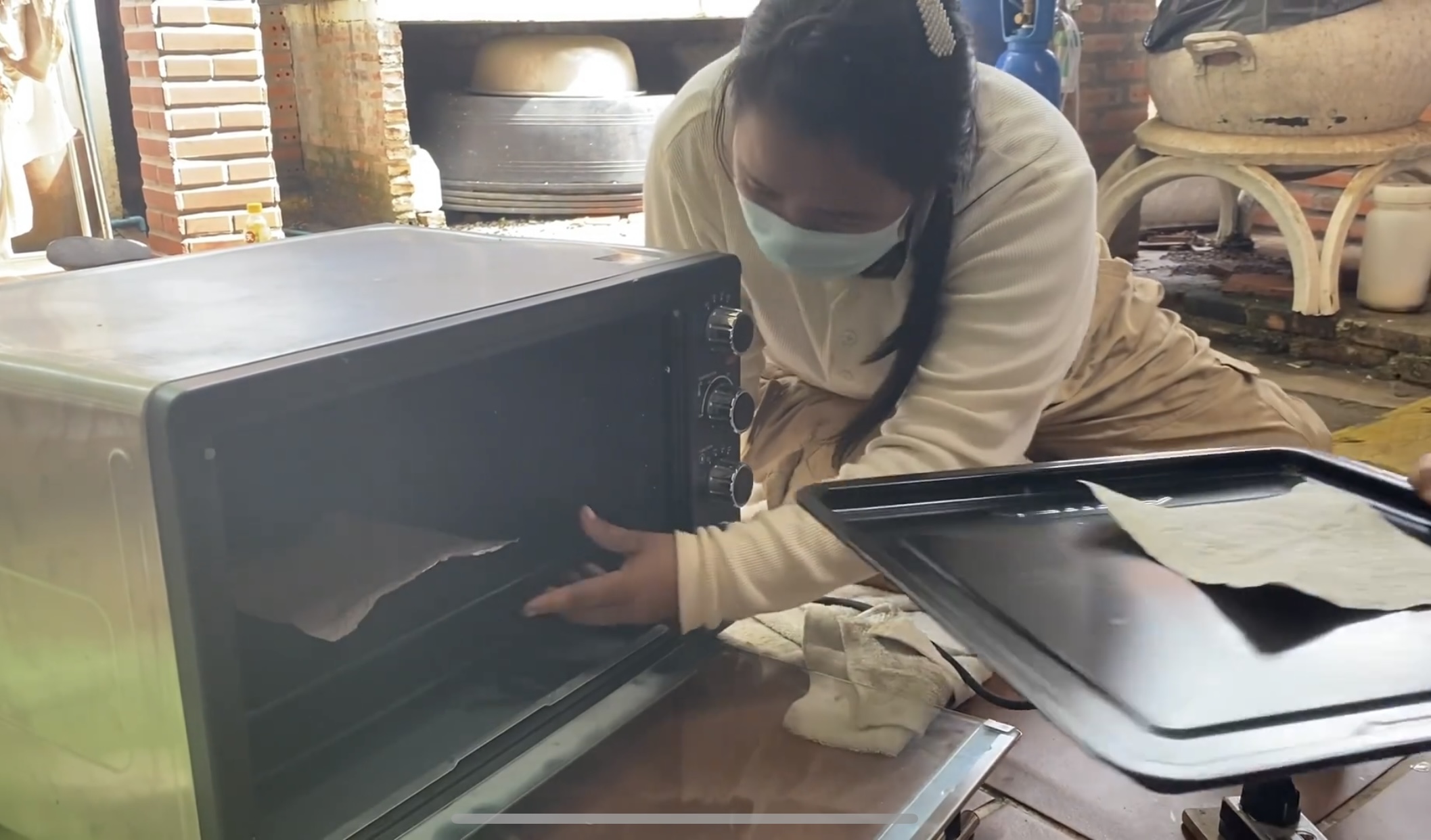

【Seeking elasticity】

We make cotton leather from things we have around us. By chance, we received a wine cork stopper, so we powdered it, mixed it with natural rubber, and baked it. The heat was too strong and burnt the material, but it turned out to be a somewhat strange feeling material.

【Safe Adhesives】

The simplest and safest adhesives are made this way. The drawback is that it takes a very long time to dry (harden by oxidation). Conversely, it is easy to make safe adhesives if you take the time.